This tool enable the drum cap sealing into leak proof and tamper proof levels. Tools are priced economically to fit the budget of low volume drum packing companies also. Tools are known as Heavy Duty because of its efficiency to crimp even 0.32 mm thickness cap seal effortlessly.

This tool enable the drum cap sealing into leak proof and tamper proof levels. Tools are priced economically to fit the budget of low volume drum packing companies also. Tools are known as Heavy Duty because of its efficiency to crimp even 0.32 mm thickness cap seal effortlessly.

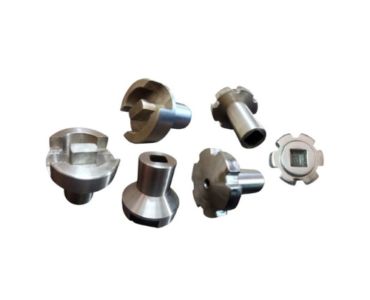

TrustSealer drum cap sealer is made of steel with adequate temper and hardness, completely hard chrome plated for long lasting, rust prevention and durability, hinges are supported by stainless steel pins and circlips.

Tools are suitable for moderate volume of drum cap sealing from light weight 10 gram seal to heavy weight 16 gram tab seals.

TrustSealer Heavy Duty Sealing Machine is ergonomically designed, so operation is even easy for an unskilled person to crimp cap seals with this crimping machines.

On request tailor made tools are available for HDPE drums, readymade tools are meant for MS drums. So for optimised plastic drum cap sealing we offer this option also for our customer.

TrustSealer is also available for 4 inch paint drum lid with same crimping attributes. Same model tools are available for flex spout sealing. These tools can seal in leak proof levels.

TrustSealer is also available for 4 inch paint drum lid with same crimping attributes. Same model tools are available for flex spout sealing. These tools can seal in leak proof levels.

Handling and storing of Machines

Tools must be handled and operated well for the quality of crimping and for the long life also.

Tools must be handled and operated well for the quality of crimping and for the long life also.

Tools must be stored safely in non saline and rusting atmosphere for the durability and performance.

Keeping the crimping part dipped in any oil will extend the life of the tools.

Tools are supported with after sale service, any impairs can be repaired. Parts including crimping jaws can be replaced after long time usage.

These tools are at affordable price.

TrustSealer – Heavy Duty Sealing Machines are available for drum capseal 2 inch & ¾ inch, 4 inch, Flex Spout 43mm and 63mm.

Specification:

Material : Steel | Mechanism : Hinges Type | Coating : Hard Chrome | No of Jaws 2” : 18 Steel | No of Jaws ¾” : 9 Steel