Drum Cap Seal

We manufacture Drum cap seal for the security and protection of the content contained in the drum. Following are the Attribution of our Drum cap seal:

1) Authentication

To authenticate the drum contains quantity, quality and legitimacy Drum Cap Seal is applied on a barrel. An universal quality capseal well sealed on the drum without flaws is an impressive mark of authentication till to the end user.

2) Protection

Drum cap seal has to fortify the bung house from entry of dirt, moisture, water and most importantly bung rusting. Hermetical (air tight) Drum cap sealing is the process to be practiced for this attribution.

3) Security

Attempt of any tampering on the drum seals should be evident and the same time cap-seal must not open without tearing into pieces.

4) Branding

Aesthetically Lithograph Printed capseal with company logo or brand promotes the product and also authenticate the legitimacy of the product.

5) Technical

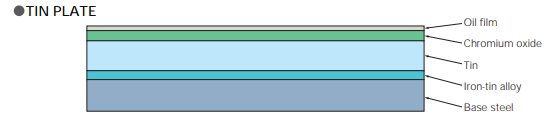

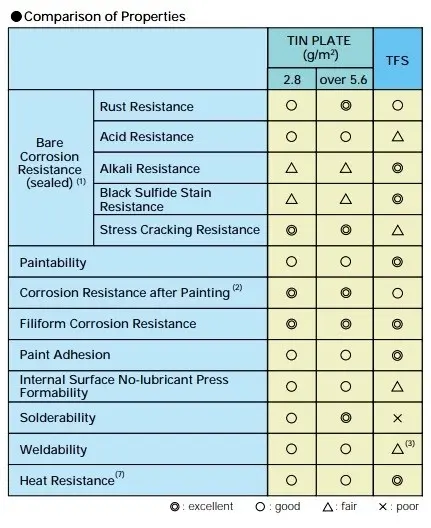

TINPLATE / TFS with a minimum 0.28 – 0.32mm thickness for rigid crimping, puffed PVC gasket and proper scoring line for removal are the technical sides of a drum cap seal.

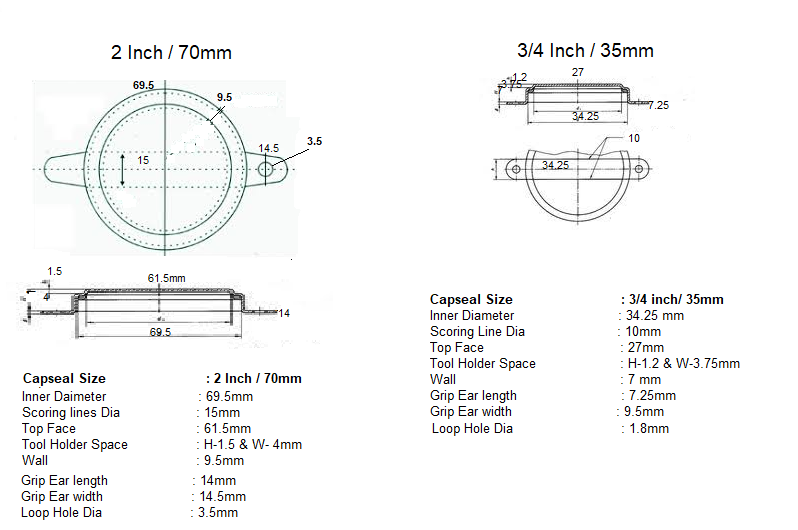

Technical Specification of Capseal:

6) Raw Material and coatings

To resist rust by weather and chemicals good quality inner lacquer coating and outer varnish coating is imperative.

” An efficient tool can only seal a drum well. “