Suitable for Metal and plastic drums. Sizes 2 & ¾ inch also known as 70mm and 35mm, 50mm and 19mm. Customized printing with logo in both lithograph and screen printing is available.

For HDPE – Plastic Barrel – Tinplate Drum Cap Seal

Tinplate tab seal is the best for sealing HDPE drums because of its thickness and foamability. At the same time these capseals are much suitable for composite drum and plastic barrels. Leakage through bungs can be arrested by these cap seals using a proper crimping tool either pneumatic or manual. HDPE drum cap sealing should be wrinkle free and tight as shown in the picture.

Tinplate tab seal is the best for sealing HDPE drums because of its thickness and foamability. At the same time these capseals are much suitable for composite drum and plastic barrels. Leakage through bungs can be arrested by these cap seals using a proper crimping tool either pneumatic or manual. HDPE drum cap sealing should be wrinkle free and tight as shown in the picture.

Leak proof drum cap sealing solution is also provided by us.

For Metal or Steel Drum – Tinplate Drum Capseal

Steel barrels are not much complicated when it comes to cap sealing. Bung house of metal drums are in standard size for 2 inch and ¾ inch. Hence using a readymade heavy duty crimping tool can deliver optimal crimping of these capseals.

Steel barrels are not much complicated when it comes to cap sealing. Bung house of metal drums are in standard size for 2 inch and ¾ inch. Hence using a readymade heavy duty crimping tool can deliver optimal crimping of these capseals.

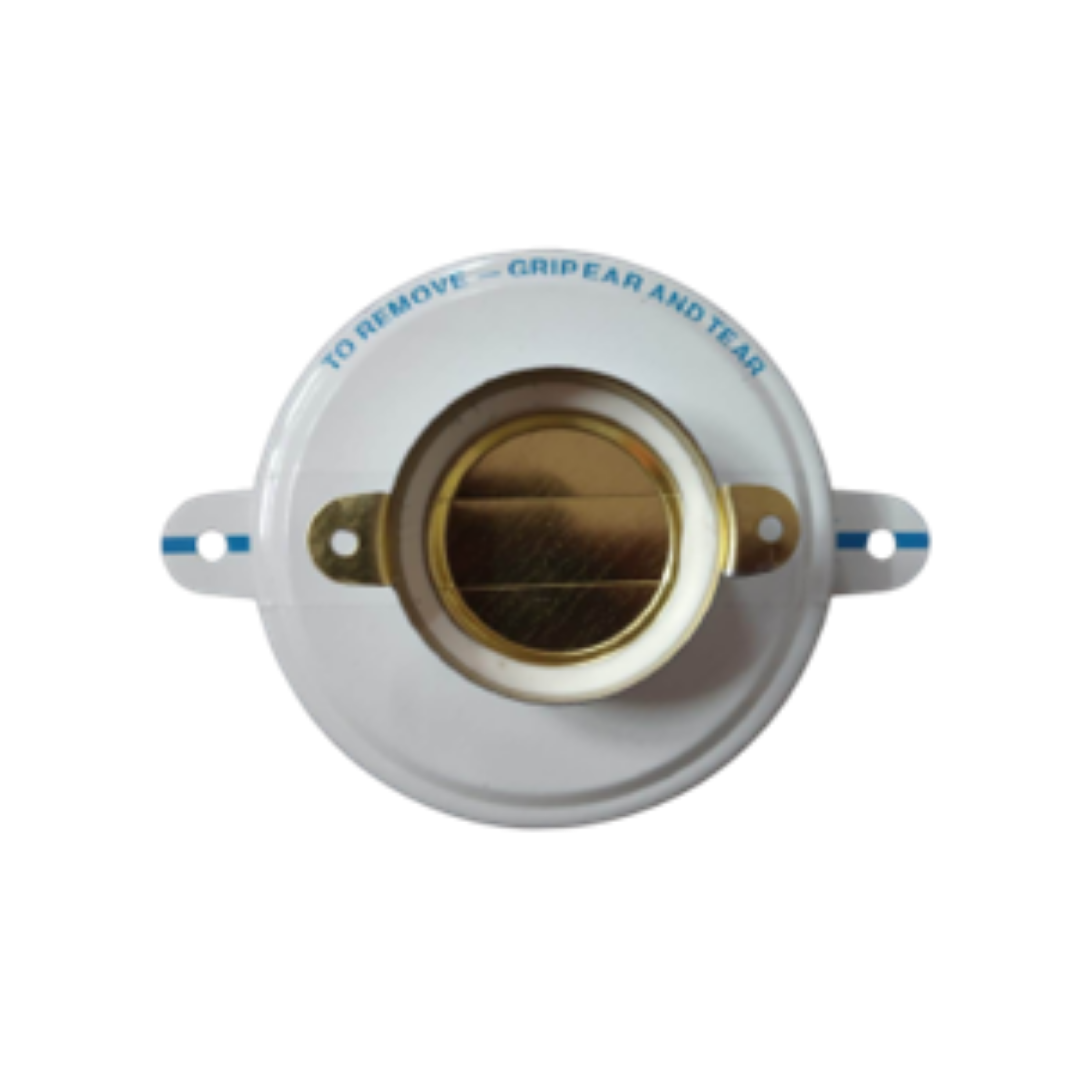

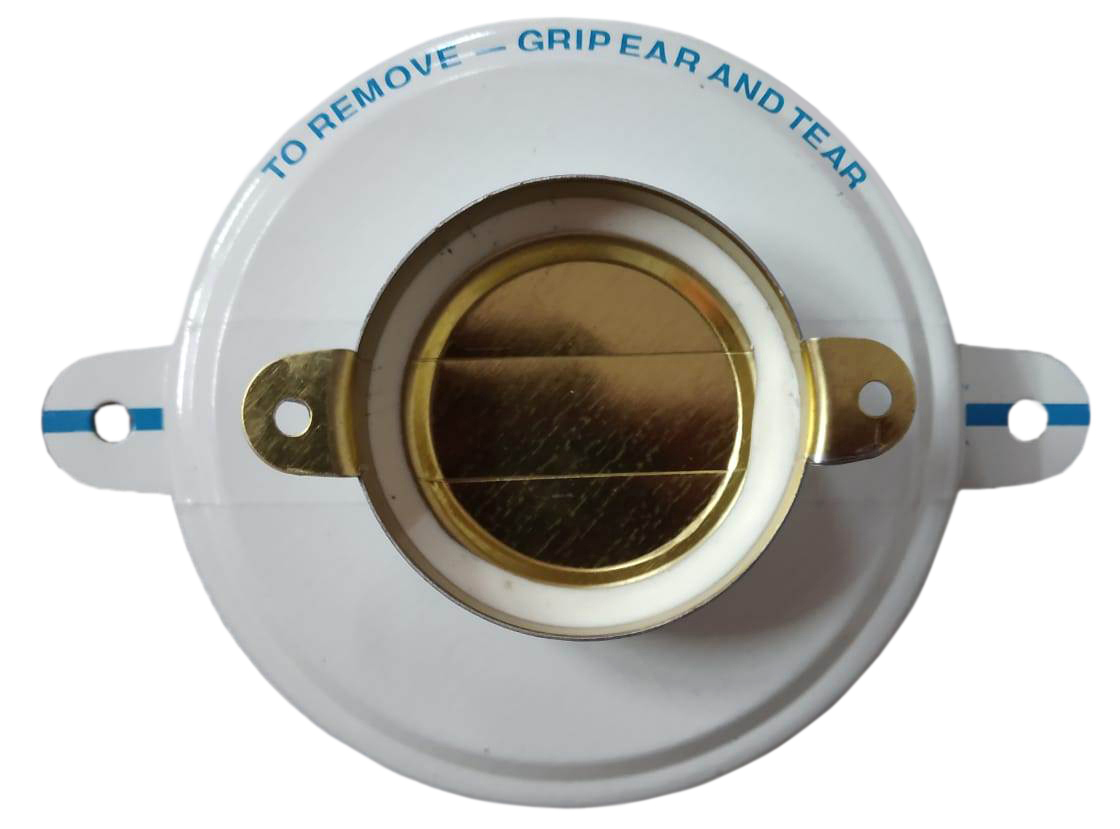

Removal of cap seal from drum.

This cap seal can be teared – off easily from the drum without applying any extra effort. This feature avoids unprecedented injuries at the event of removal of tab seal with screw drivers and chisel.

This cap seal can be teared – off easily from the drum without applying any extra effort. This feature avoids unprecedented injuries at the event of removal of tab seal with screw drivers and chisel.

Specification:

Size: 2 Inch & 3/4 Inch | Material: PRIME TINPLATE | Thickness: 0.28 – 0.30mm | Weight: 2 Inch: 14 – 15 gram, ¾ Inch:4 – 4.5 gram | Available: Plain / Printed |

Suitable for: Long duration Transport & Storage. Rust Resistant |Food Grade: Available on request.