Capseals are applied for the security and protection of the content contained in the drum. Following are the Attribution of cap seal:

1) Authentication

Capseal is a symbol of trust, caps well sealed on the drum authenticate the quantity, quality and legitimacy of the product. Universal quality cap seal crimped with an efficient tool without flaws is the right practice for this.

Well sealed drums

Falsely sealed drums

2) Protection

Cap seal has to fortify the bung house from the entry of dirt, moisture, water, vise-versa it should arrest any bung leakage not to flow-out. Hermetical (air tight) cap sealing is the best protection for drum contains and most importantly prevents bung rusting.

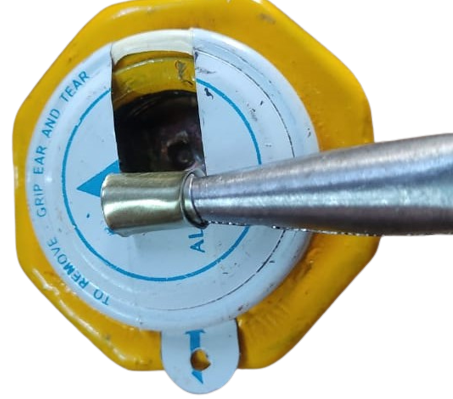

3) Security

It means security from tampering, pilferage and adulteration. Once crimped the cap-seal should only open by tearing into pieces. For rigid and tight crimping a thickness of 0.28-0.30mm is required for tamper resistant strength and it is imperative, thus tamper attempt will go into vain. This is enabled with an efficient crimper and sealer .

4) Branding

Aesthetically Lithograph Printed Cap seal with company logo or brand promotes the product and also authenticate the legitimacy of the product .

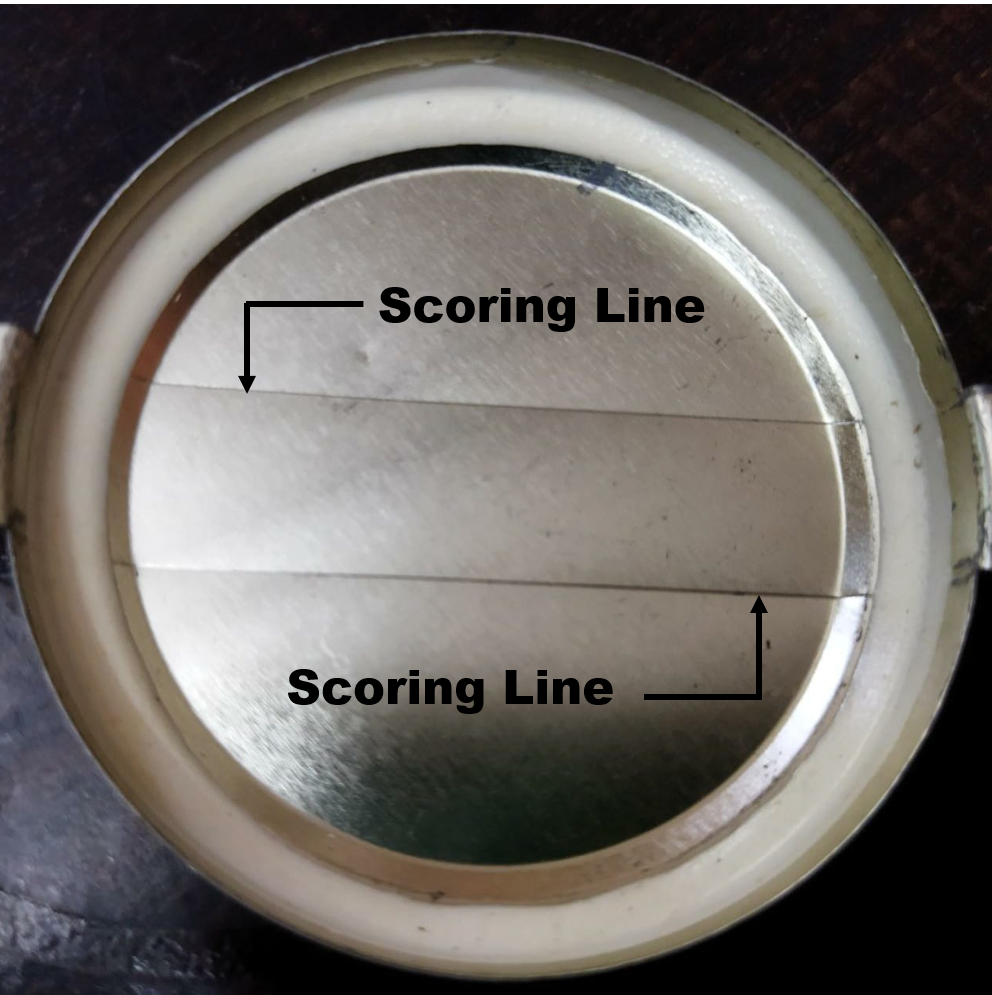

5) Technical

Is the most important aspect of the capseal. Thickness of the tinplate should not be less than 0.28mm for tamper resistance strength. Inside scoring lines punched well for easy removal of the cap seal. Puffed PVC inner gasket for leak resistant.

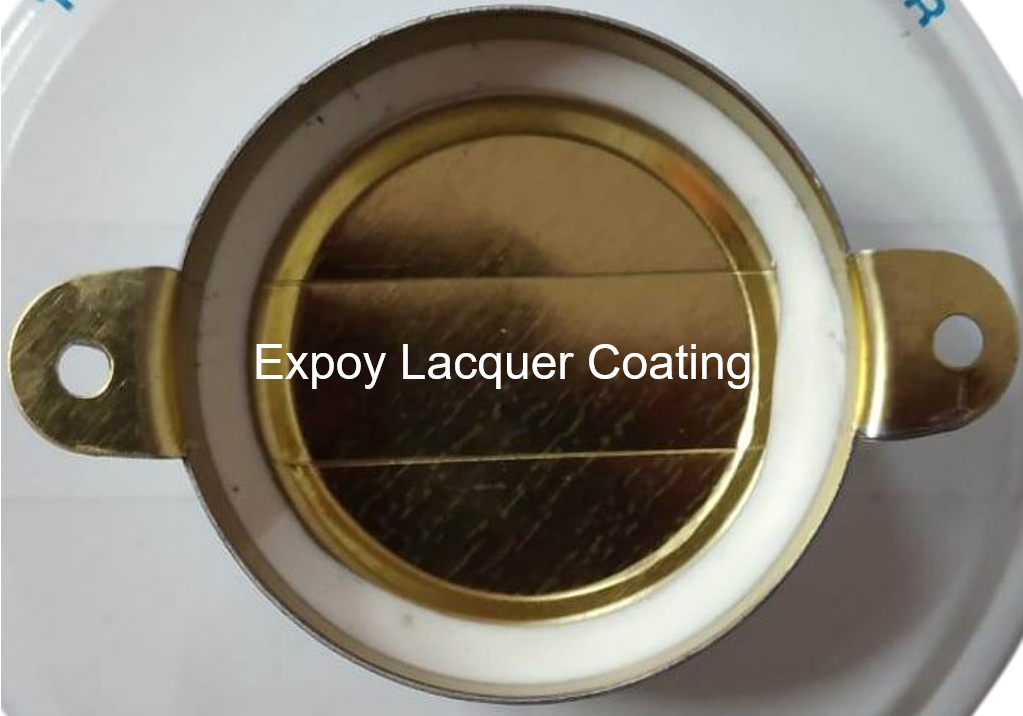

6) Inside lacquer coating

There are two types of lacquer coating to resist rust and chemicals. Ordinary lacquer and Epoxy lacquer among the both epoxy lacquer can sustain to chemicals. Ordinary lacquer is vulnerable to chemical and rusting. This type of coating is used in ordinary or local cap seals.

Capseals without inside lacquer coating is prone to rusting and in due time rusting will spread in the bung house, rust can even affect the contain inside the drum.

Outer acrylic varnish coating to hold the printing and colour coating against chemicals and weather, Ordinary varnish is prone to rusting fast, so acrylic or epoxy varnish is advisable.

Capseal printed with ordinary varnish can be vulnerable to chemical. Printing can erode as shown in the image which will spoil the product authenticity and company value.

What quality means?

Quality means “Performance upon expectations” and “fit for functions.”

A product is said to be of good quality if it satisfies the customer requirements in terms of performance, grade, durability, appearance and intended use/purpose, etc.